We are pleased to welcome our current and future partners and offer a wide range of bearings manufactured in Latvia under the proprietary brand of «BBC-R».

You are kindly invited to become our partner and visit our plant in Riga (Latvia).

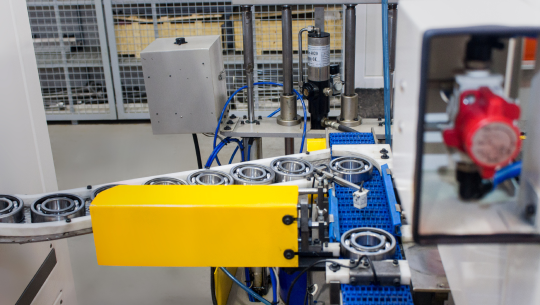

More than 200 units of modern high-precision equipment have been installed in production workshops.

The quality management system extends to the development, production and supply of bearing products to consumers.

An integrated system for the efficient use of vehicles and warehouses ensures maximum delivery speed.

The company employees have a great experience in the bearing industry. Many of them worked in the leading bearing companies.

Each batch of components for the production of bearings passes input control according to the drawings.

The company is trying to minimize its impact on the environment and the use of harmful chemicals.

Leave a request. Our specialists will contact you as soon as possible and will advise on all issues and questions absolutely free.