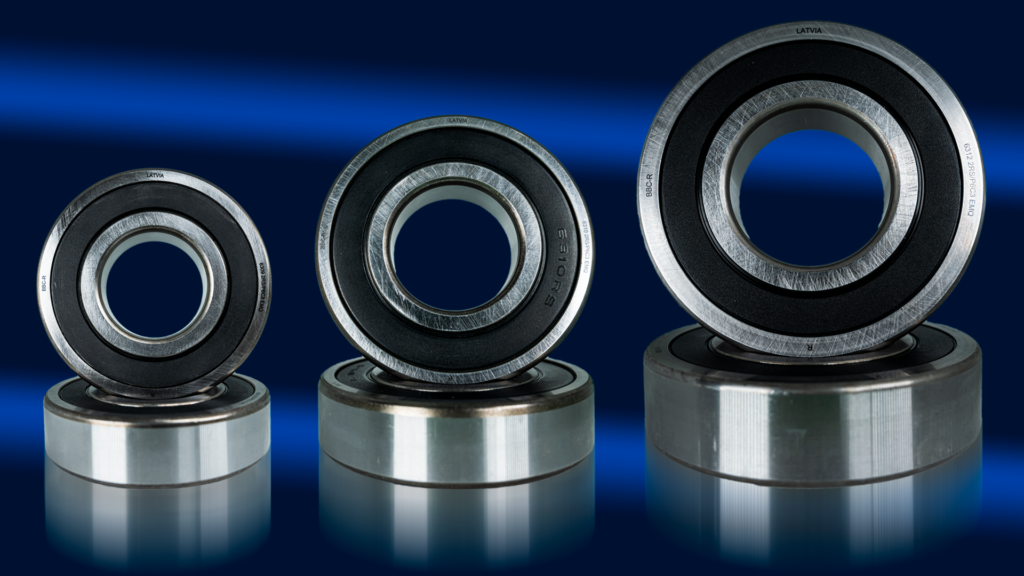

The electric motor is the heart of the mechanism. And the heart of an electric motor is a rolling bearing, which is one of the most important elements for converting electrical energy into mechanical energy. The quality and technical characteristics of the bearing determine such parameters as noise and vibration of the engine, the rotational speed of its elements, the temperature range of the unit and, as a result, its durability and efficiency. BBC-R EMQ bearings are specially designed for electric motors based on modern engineering solutions of the Baltic Bearing Company-Riga in the field of mechanical engineering.

The manufacturing process for the BBC-R EMQ series bearings includes turning, heat treatment, grinding and automatic assembly.

A consistently high level of quality and control of all necessary technical requirements is ensured at every stage of the production of BBC-R EMQ bearings.

Products:

BBC-R EMQ – deep groove ball bearings of special requirements of noise and vibration level with standard grease for ZZ and 2RS types.

BBC-R EMQ plus – deep groove ball bearings of special requirements of noise and vibration level with specialized grease (according to customer requirements or specific features of the unit)

Production:

– High quality bearing steel 100Cr6 (ISO 683-17) is used for the production of BBC-R bearings. The workpiece for the EMQ series undergoes additional control according to the most important reqirements of the physicochemical properties of the metal.

– Automatic control of temperatures in the zones of heat treatment is carried out, control of the hardness of the parts after heat treatment; 100% automatic control and correction of dimensions during grinding; automatic assembly with 100% control of such parameters as outer and inner diameters, their variability, radial clearance, vibration level.

– Additional requirements for the microgeometry of working surfaces are provided by modern technological solutions during their grindind processing.

– The Plant laboratory controls the stability of the microgeometry of the working and mounting surfaces using precision equipment from leading manufacturers.

– Using of the best greases developed in cooperation with FUCHS (Germany) for different temperature ranges.

– design options: open, ZZ type, 2RS type.

Advantages:

– increased maximum speed;

– extended temperature range;

– reduced noise and vibration level.

Application area:

Induction and synchronous motors.

Also read:

Baltic Bearing Company – Riga. History of BBC-R building (bbcr.eu)

Quality Management System of Baltic Bearing Company – Riga. (bbcr.eu)

Measure thrice and assemble once | European bearing manufacturer «BBC-R» (bbcr.eu)

And watch us at Youtube: